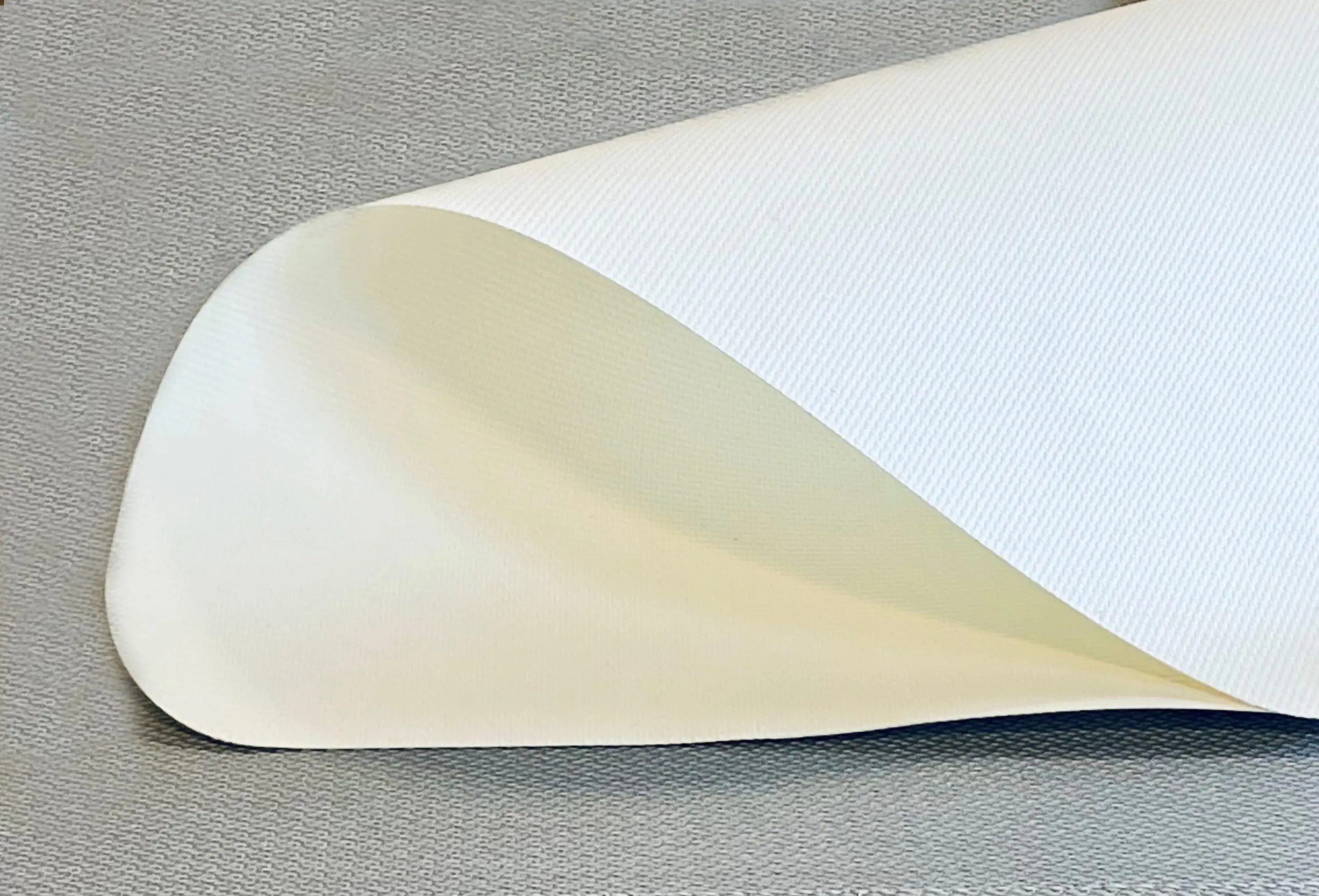

Silicone-coated fiberglass fabrics are manufactured for use in a range of applications where high heat or flame resistance is required, as well as high levels of resistance against abrasion, chemicals, UV rays and weather conditions that could cause damage. Throughout this blog post, we will look at the properties of silicone-coated fiberglass and what applications it is used in.

The Properties of Silicone-Coated Fiberglass

Silicone-coated fiberglass can be beneficial for several reasons, but in this post, we will focus on why silicone is used to coat fabrics. Mid-Mountain manufactures a range of silicone-coated fabrics under the ARMATEX® label, which uses a variety of substrates coated with silicone rubber compounds. This material then provides a number of key features.

- Abrasion and Corrosion Resistant

- Chemical Resistant

- Durable (working temperatures of -70oC to 550oC)

- Flexible

- Flame Resistant

- Heat Resistant

- Oil and Water Resistant

- Weather Resistant

- Weight Range (7 oz/sy to 90 oz/sy)

In addition to the above properties, we are able to produce silicone-coated fabrics in a range of colors, and they can be customized to suit your specific needs.

The Applications of Silicone-Coated Fiberglass

Silicone-coated fiberglass is made of glass fiber cloth and coated with silicone rubber. Often referred to as silicone-coated fiberglass cloth, the fabric is typically engineered for use in industrial applications where high levels of resistance are required against extreme temperatures, flames and chemicals. Mid-Mountain can manufacture silicone-coated fiberglass fabrics to fit your applications, but examples of where the ARMATEX® range has been used include the following:

![]()

![]()

Aerospace Industry

Fiberglass fabrics are ideal in specific applications such as airbags, aircraft walkways, cargo covers and onboard flame retardant fabrics. Heat-resistant fabrics are vital for keeping personnel and equipment safe but are also high in strength.

Industrial Protection

Silicone-coated fabric can be used to protect both machinery and workers from high temperatures. This includes conveyor belts of drying machines, equipment covers, gaskets, lining and liners in equipment and welding curtains.

Aluminum Industry

Due to the high resistance properties of fiberglass, ARMATEX® silicone-coated fabrics and ropes are frequently utilized in the aluminum industry. It is used to manufacture external cathode bar seal boots, anode bar seals, crucible lid seals and other components for every area of a primary aluminum smelter.

Thermal Insulation

As an insulation product, the silicone-coated fabric is an ideal choice because of its chemical and heat-resistant properties. Blankets, curtains, removable insulation pads and seals are popular thermal insulation products for our ARMATEX® range.

Mid-Mountain’s Range of Silicone-Coated Fiberglass Fabrics

Mid-Mountain manufactures a range of ARMATEX® Silicone Coated Fabrics, Tapes and Ropes for industrial applications that require high levels of resistance to abrasion, chemicals and high temperature.

Our products include the following:

- SF 10-NF: This product is manufactured using lightweight fiberglass fabric and silicone rubber. It is highly resistant to abrasion and flames, making it a solid choice for applications that protect personnel and equipment.

- SF2 12-NF: A high-performance fiberglass fabric coated with a polymer coating. This fabric is used in the aerospace industry for cargo liners and smoke curtains due to its fire retardant properties as well as being weather and UV resistant.

- SF17 Premium: The SF17 is manufactured with a strong woven fiberglass fabric and silicone rubber on both sides. It has been designed to exceed industry standards and is an ideal solution for thermal insulation requirements.

If you are ready to purchase an ARMATEX® Silicone Coated Fabric or require any additional information, get in touch with us today and let’s find the perfect solution for your application.