SPECIALTY COATED FABRICS

Mid-Mountain Materials, Inc. manufactures advanced, high-performance coated fabrics for use in unique applications across a broad range of industries. Utilizing some of the most advanced fibers, specialized weaves, and a variety of blends and coatings, our specialty line of ARMATEX® Coated Fabrics deliver not only superior heat protection, but have exceptional durability and resistance to chemicals, abrasion, and weathering.

In partnership with our customers, Mid-Mountain has developed innovative, specialty coated fabrics for use in technical applications such as air cargo covers, robot protective covers, aircraft jet bridges, and temporary wilderness shelters. In addition to fiberglass and silica substrates, we utilize specialty fabrics including Nomex®, Kevlar®, nylon, carbon, and aramid blends, and coat with a variety of high-temperature, chemical, and abrasion-resistant coatings.

Product Search

Robot Protective Covers

Robots improve the quality of work by taking over dangerous, tedious, and dirty jobs that are not possible, or safe, for humans to perform. But today’s complex manufacturing processes put Robotic equipment in danger, therefore it is extremely important to protect the robotic equipment in damaging and abusive environments. In response to this need, we developed ARMATEX® SBN 13-602 ROBOTEX™, which is used in the fabrication of Robotic Protective Covers as a means to protect the investment of the robot and reduce maintenance-related downtime.

Developed with a very high strength polyamide base fabric and a high-performance coating, ARMATEX® SBN 13-602 ROBOTEX™ has uncompromising flexibility, as well as very high strength and resistance to extreme conditions. Testing has concluded that ROBOTEX™ lasts longer than conventional robot clothes, and maintains its integrity in severe conditions. In addition to manufacturing the coated fabric, Mid-Mountain has the capability to fabricate the robot clothes as well.

Cargo Protection

Following a federal investigation into fire-related cargo compartment accidents, Mid-Mountain developed a coated fabric that contains deadly smoke and fire in cargo bays, preventing the fire from escalating. Manufactured using a high-performance fiberglass fabric and an innovative polymer coating, ARMATEX® SF2 12-NF can be used as flexible cargo containers, pallet covers, smoke curtains, and cargo liners for aircraft.

The primary purpose of a cargo liner is to prevent a fire that has originated in a cargo compartment from spreading to other parts of the airplane. Flame resistant pallet covers are used primarily to protect cargo from a fire in the compartment, but can also protect cargo from weather extremes when placed on the tarmac during the unloading process. ARMATEX® SF2 12-NF has enhanced strength and flame resistant properties and is both weather and UV Resistant. Lightweight and flexible, ARMATEX® SF2 12-NF is ideal for use in any application that requires a fire retardant material.

Ideal for use in Thermal Insulation Blankets and Pads

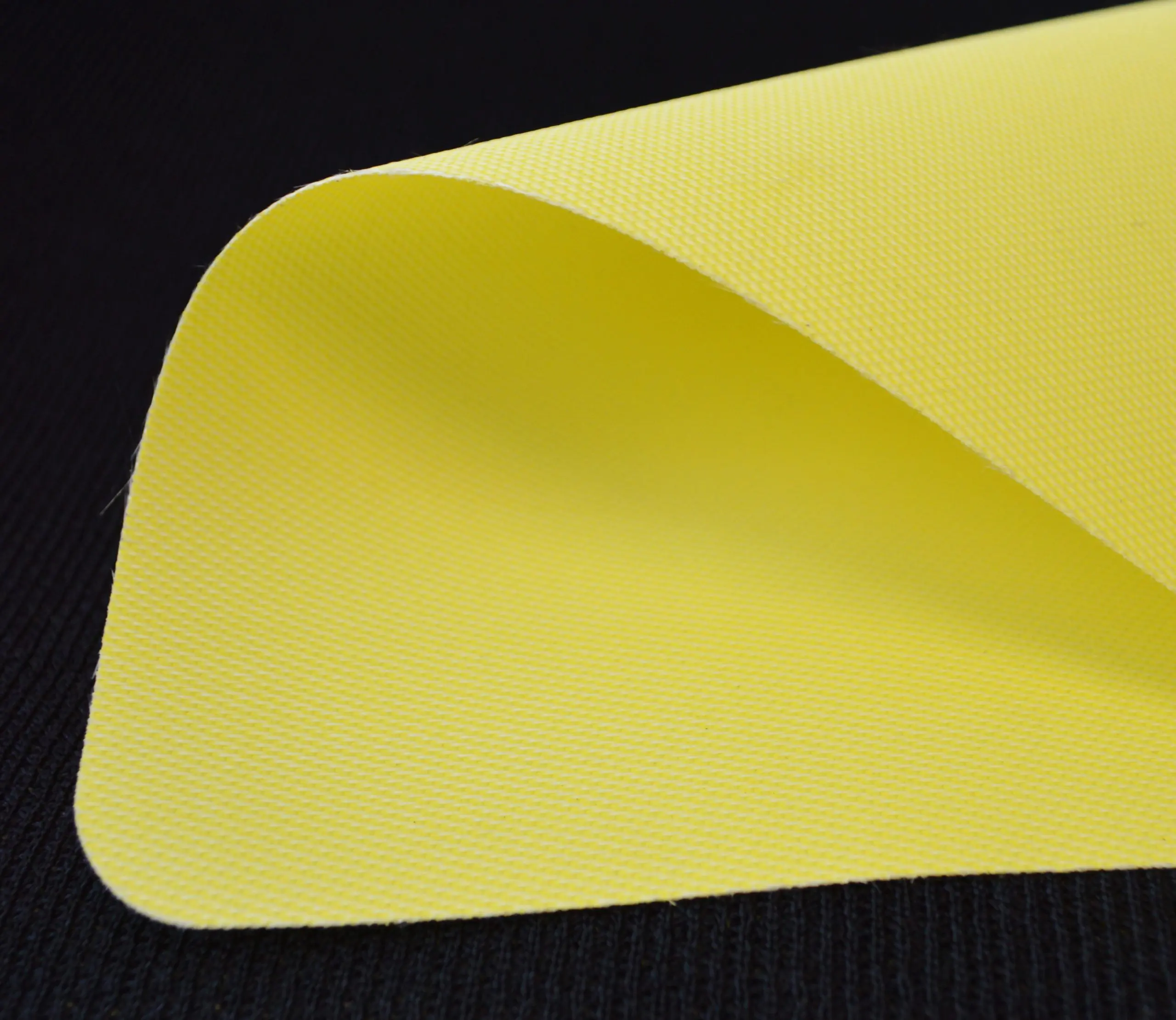

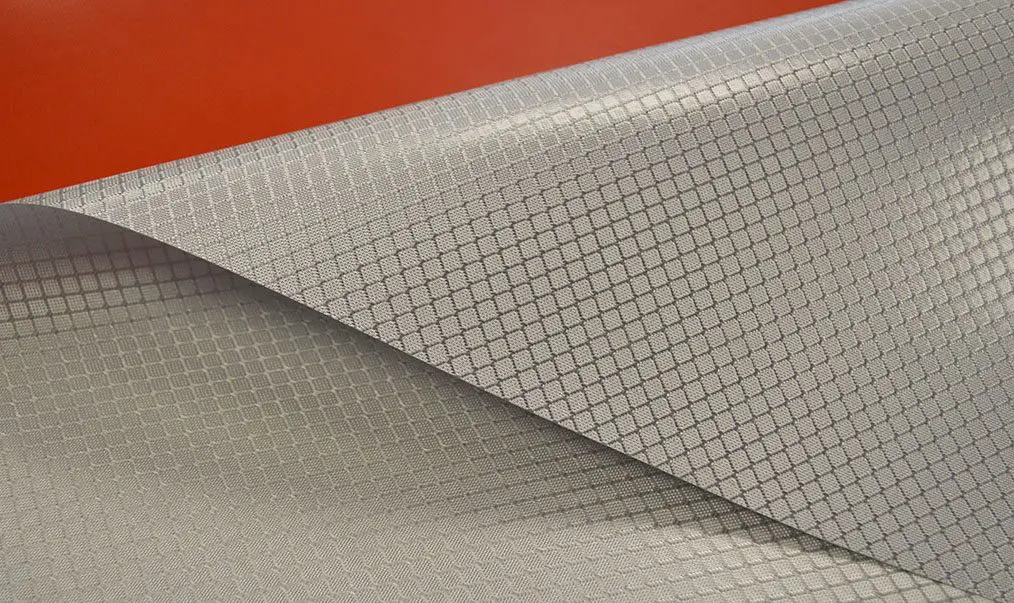

If you have an application where aesthetics are important, and both high-temperature resistance and abrasion resistance are required, ARMATEX® SilverStar is the perfect solution. Developed in response to the demand for a more aesthetically pleasing fabric, ARMATEX® SilverStar has increased thermal properties due to the reflective coating, and a very unique weave pattern which sets it apart from other coated fabrics available in the industry today.

This coated fabric can be used in traditional mechanical insulation applications for fabricated blankets and pads, and is excellent for use if color coding is required. Available in weights of 10 oz/sy and 13 oz/sy, the light weight makes it very easy to fabricate with and handle.

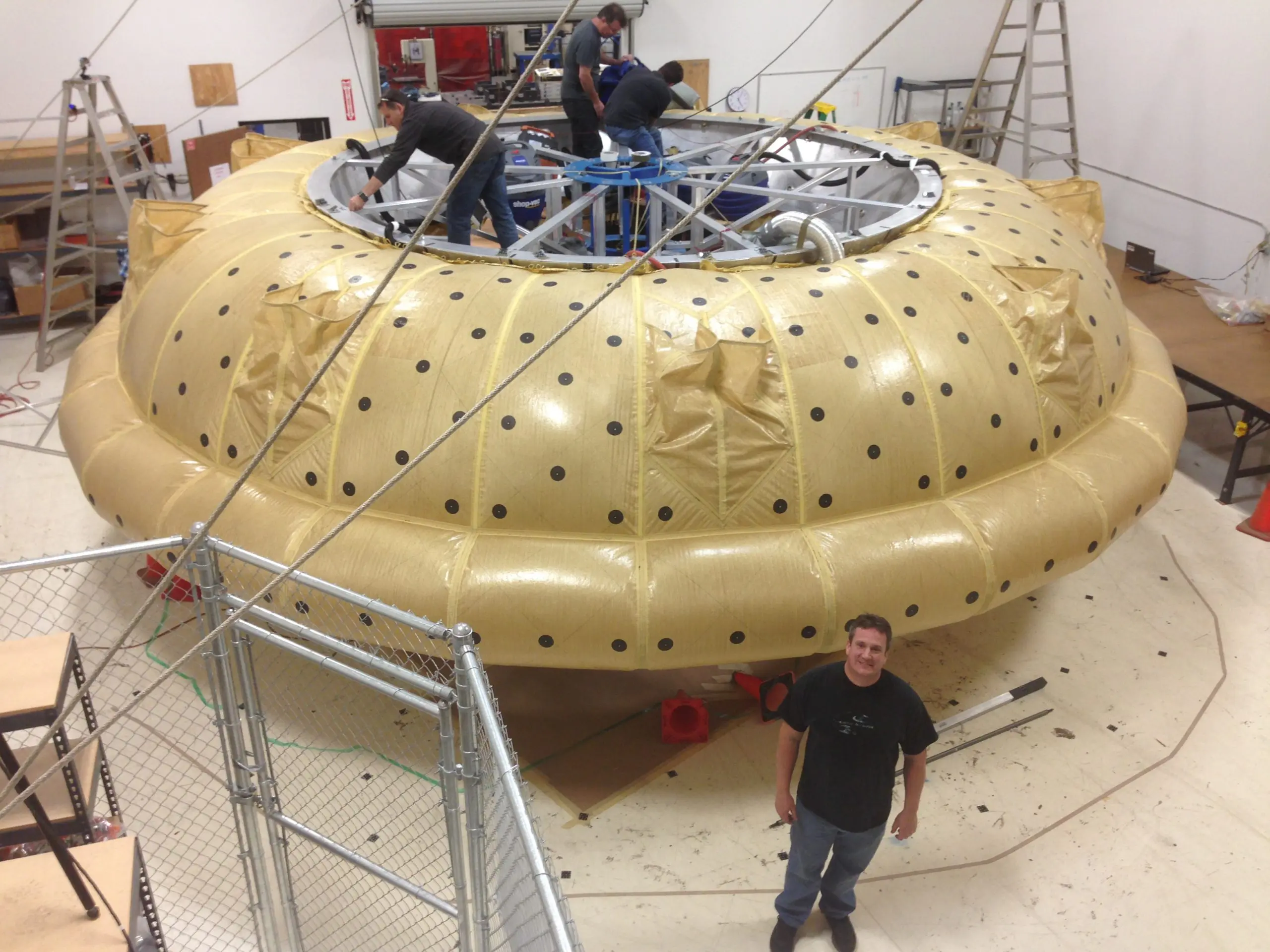

A trip to Mars

In 2020, NASA was scheduled to test a Supersonic Inflatable Aerodynamic Decelerator (SIAD-E) that would be capable of landing larger aircraft on Mars. The SIAD-E is inflated by a combination of gas generators and ram air inlets, allowing it to fully deploy in less than 2 seconds in conditions up to Mach 4. Acting as a “ballute” (ballon/parachute) the purpose of the SIAD-E was to inflate before landing, decelerating the lander for an effective and safe approach.

In advance of 2020, Mid-Mountain was asked by NASA to overcome the challenges of this application. In partnership with JPL and Air Born Systems, our engineers developed a unique coating technique that applied silicone to a heat-sensitive, dimensionally unstable braided fabric without applying high heat or web tension. Unfortunately sensors could not be attached to the fabric, and it was not used on the 2020 Mars Lander. However, it remains an excellent illustration of Mid-Mountain’s coating capabilities and problem-solving approach to challenging application requirements.

Coated Fabric for Passenger Boarding Bridges

ARMATEX® SF 37 Jetstar was developed specifically for use as flexible canopies for passenger boarding bridges. A major objective of airport operations is moving passengers between the terminal and the plane safely and efficiently. This coated fabric exhibits superior strength as well as flexibility and is highly resistant to abrasion, fire, and weathering, which makes it an ideal product for any type of flexible closure assembly, including those used in ports.

ARMATEX® SF 37 Jetstar meets or exceeds the requirements of NFPA Specifications 417, 255 and 701*, and is classified as “Class A” per NFPA 101, Life Safety Code.

*NFPA 701, Section 8-6, Accelerated Weathering is a prerequisite for the test specimen to be tested in, and in accordance with, NFPA 417.

Behind all of the specialty coated fabrics, we have developed was a customer who had a unique application requirement that could not be addressed with a standard coated fabric. Research and Development are at the core of what we do, and we would be happy to assist you with a solution tailored to your needs.

Have a question?

Send us some information about what you’re looking for. Finding the right solution for industrial applications is what we do best.