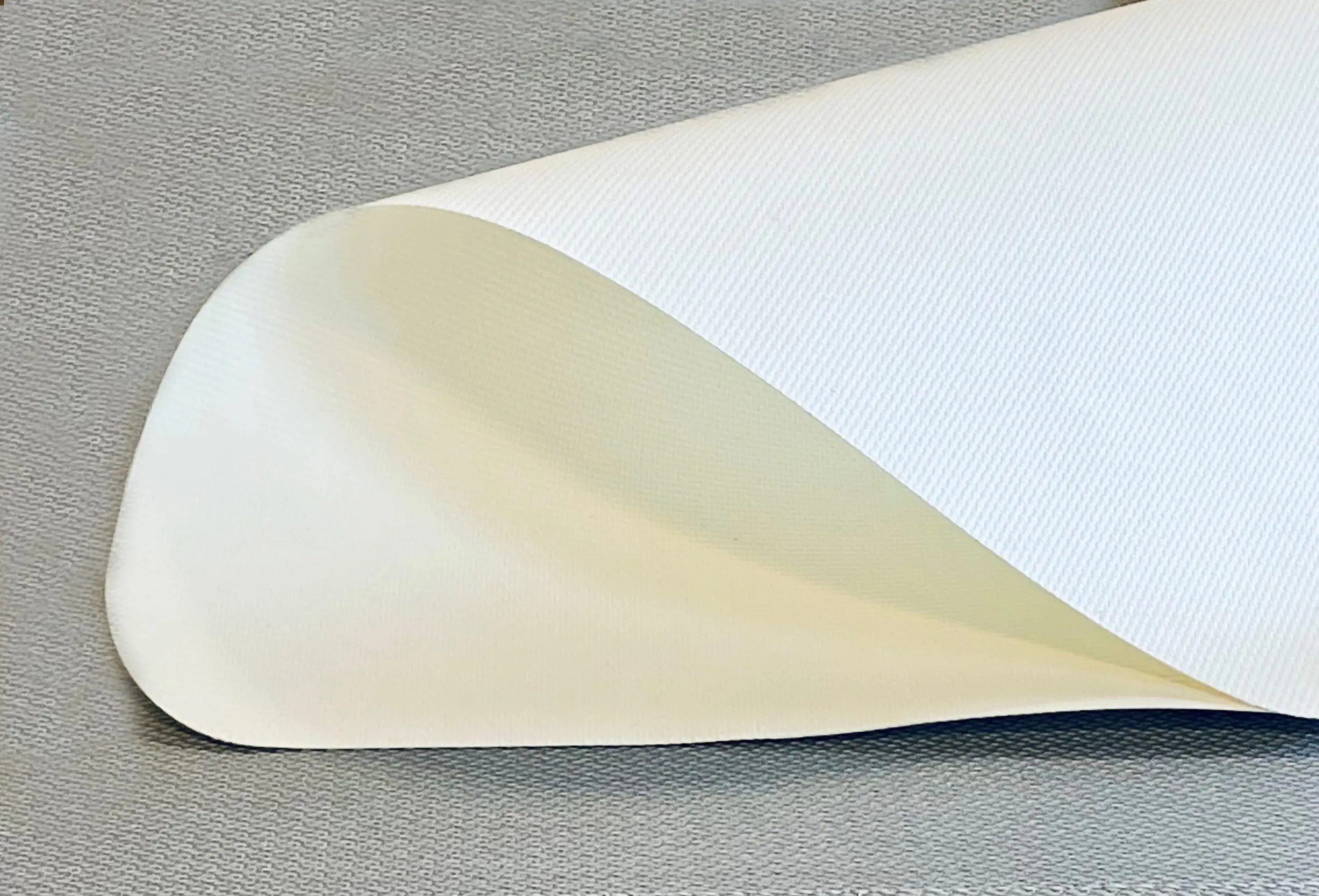

Silicone glass fabric is a material that provides outstanding heat-resistant properties for a wide range of applications. The material is coated on both sides with a silicone rubber that has been specially designed to provide benefits for several purposes. Throughout this blog post, we will outline what silicone glass fabric solutions are available and their benefits.

SILICONE GLASS FABRIC APPLICATIONS

As a highly flexible material, silicone glass fabric is frequently used in industrial applications where high heat resistance is required. In addition to its heat resistant properties, it is also abrasion resistant, chemical resistant and has strong water repellency.

Die-Cut Gaskets

Die-cut gaskets are placed between two pieces of material to work as a seal. Considerable force is used to compress the seal, which is then able to fill any gaps, prevent abrasion and reduce the likelihood of leaks. Silicone glass fabric is used to manufacture gaskets because it has outstanding chemical and temperature-resistant properties.

Thermal Insulation

Silicone glass fabrics can be used as thermal insulation barriers. The role of this fabric is to reduce how much thermal energy is transferred between two objects. These thermal insulation barriers are essential when two objects have different temperatures, which could seriously affect performance and quality after the heat transfer. These materials are frequently used in aerospace, power generation, and robotics to prevent heat transfer and keep personnel safe.

Welding Fabrics

For workplace safety in welding environments, silicone glass fabrics can be used to manufacture blankets and curtains. These fabrics help keep personnel safe by resisting high temperatures and sparks from the machinery.

It is worth noting that silicone glass fabric can be divided into three categories, each of which has different characteristics and specifications. Heavy-duty, medium-duty and light-duty silicone-coated glass fabrics can be used for various purposes.

Heavy weight silicone glass fabrics are most suitable for protection in crude industrial processes, and it is can be produced as belts, strips, seals, curtains and blankets. It can also be used in the rail industry as fabricated spark curtains which contain sparks during the rail grinding process, and for use as a seal in extreme environments such as aluminum smelters.

![]()

Medium weight silicone glass fabrics are ideal solutions for protecting workers in the welding industry, as well as insulation jackets and insulation blankets in the mechanical insulation industry. Light weight silicone glass fabrics are typically used as barriers and curtains in applications requiring high-temperature resistance such as robot covers or cargo bay liners and pallet covers. One or two-sided coating is available for the light-duty fabric.

THE BENEFITS OF SILICONE GLASS FABRIC

As we have already mentioned, silicone glass fabric provides various benefits to the applications it can be used in. Aside from being highly chemical and temperature resistant, a few additional benefits are worth considering:

- Ability to Handle High Pressure

- Electrical Insulation

- Flame Retardant

- High Strength

- Lightweight Fabric

- Smoke Resistant

- Strong Thermal Insulation Properties

- Resistant to Aging

- Water Resistant

- Weather Resistant

- UV Light Resistant

SILICONE GLASS FABRIC SOLUTIONS AT MID-MOUNTAIN MATERIALS, INC.

There are many silicone glass fabrics available at Mid Mountain Materials, Inc.. We manufacture these for use in industrial applications that need materials with high resistance levels to abrasion, chemicals, flames or high temperatures. Additionally, these fabrics range in weight from 7oz/sy to 90 oz/sy.

Please contact us today if you would like more information on the fabrics we manufacture or how silicone glass fabric could support your applications.