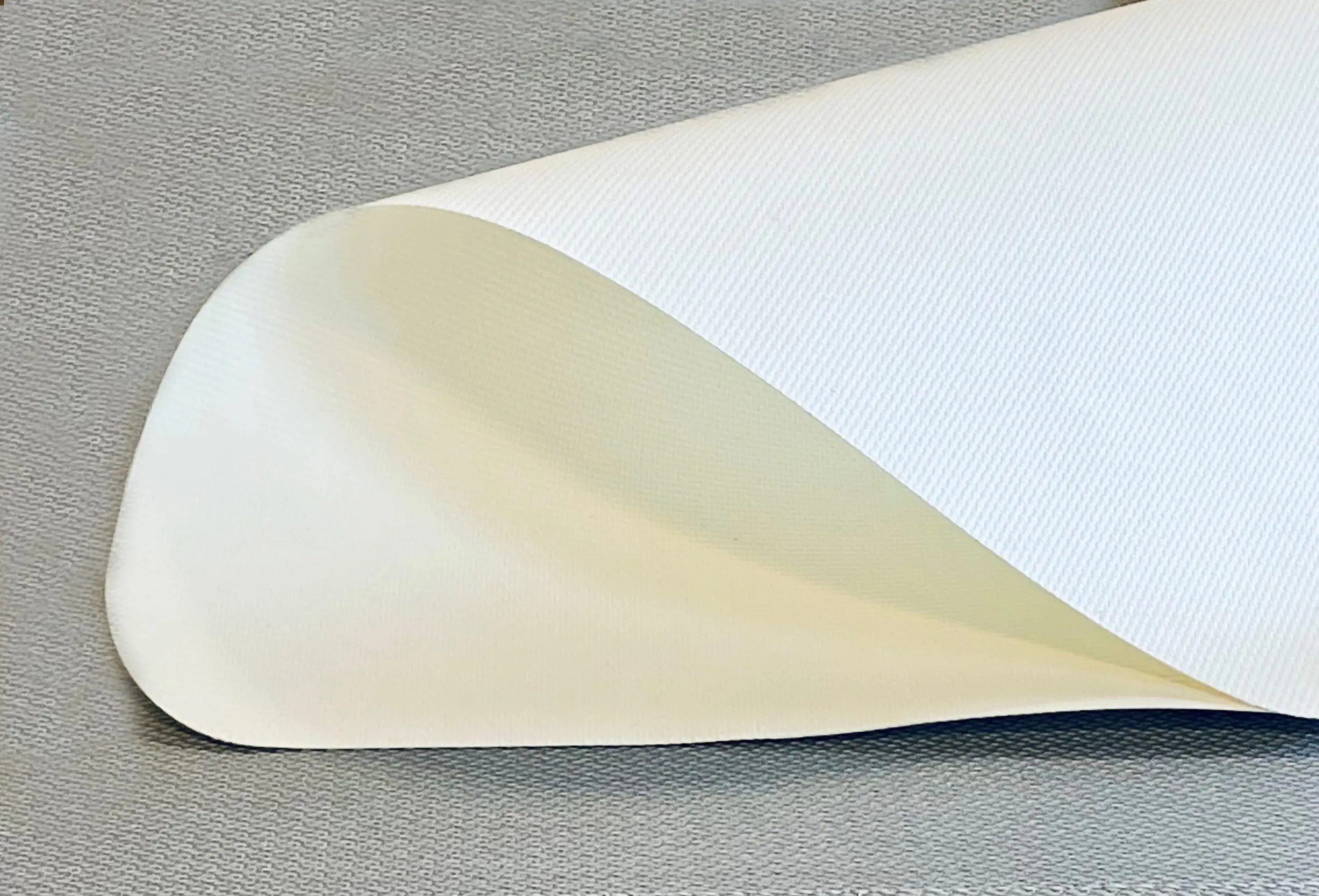

Silicone-coated glass fabric is a material that is coated on both sides with specially formulated silicone rubber. Silicone is an excellent choice for heat-resistance applications because it is highly resistant to aging, weathering, and UV light. It is also water-resistant and smoke and flame retardant. In this article, we detail the key characteristics of silicone-coated glass cloth and its main applications.

Main Types of Silicone Glass Fabric

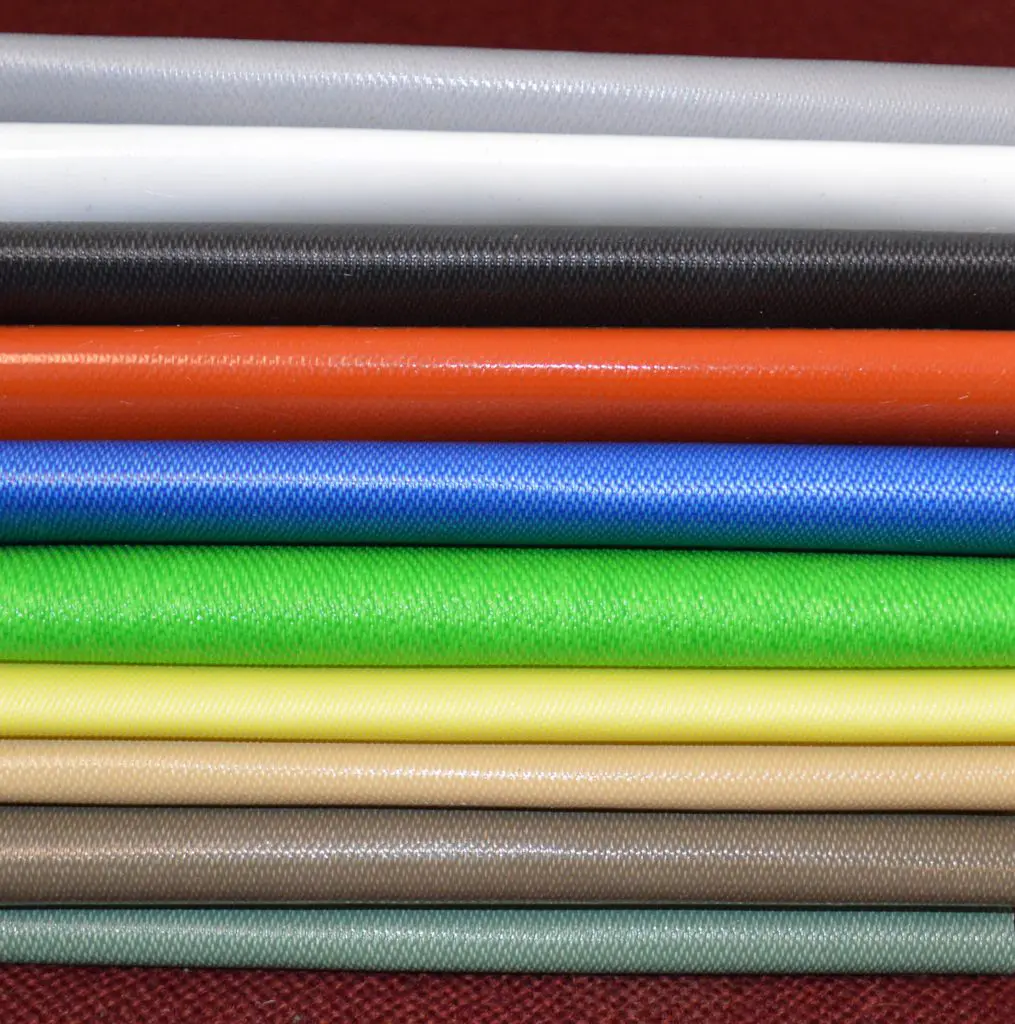

Silicone glass fabrics come in a range of specifications with differing characteristics.

Heavy-duty silicone glass fabric is often produced in belts and strips. This type of fabric is used to safeguard cables and hoses from harsh industrial conditions. This specification of material can be used for molten splash and slag applications.

Medium-duty silicone glass fabric comes in the form of a one or two-sided coating on a fabric. This type of fabric offers excellent protection from welding splatter and frequently finds use as a cold side shielding on insulation blankets.

Light duty silicone coated glass fabric can be one-sided or both-sided silicone coated glass fabrics. These fabrics are often employed as curtains and barriers in high-temperature applications.

Applications of Silicone Coated Glass Fabric

Thermal Insulation Barriers

Thermal insulation barriers work to minimize the transfer of thermal energy that takes place between two objects. When two objects have different temperatures the transfer of heat could result in significant consequences for performance and quality. Silicone glass fabric has excellent thermal insulation qualities and as such is well-suited to thermal barrier applications. A medium weight coated glass fabric (17 oz/sy) is often used in power generation to wrap the steam pipes for personnel protection.

Thermal insulation barriers find use in a range of industries. In the aerospace industry, they help to ensure that the heat generated by jet engines does not transfer to the cockpit and the cabin. They are also used for protection in the cargo bay, either as cargo bay liners or pallet covers.

In robotics applications, thermal insulation barriers are used to stop degradation of the robot that might occur in harsh operating conditions.

Die Cut Gaskets

Die-cut gaskets work as a seal placed between two surfaces. When a compressive force is present, a die-cut gasket seals the gap between both surfaces. It also mattifies the surface, filling in any potential design defects. Gaskets are often required high-temperature resistance and must be chemically compatible. Silicone-coated glass fabric is beneficial for these applications due to its excellent temperature and chemical resistance properties as well as its ability to handle high pressure.

Welding Fabrics

Fabrics such as blankets, curtains, and drop cloths are essential for managing safety in welding workspaces. These fabrics need to offer high levels of heat resistance and flame retardance as they will be exposed to high levels of heat and sparks from the machinery.

Silicone Glass Fabrics from Mid Moutain Materials, Inc.

Mid Mountain manufactures a range of silicon glass fabrics that are created for use in industrial applications that require abrasion, flame, chemical, or high-temperature resistance.

The fabrics range in weight from 7 oz/sy to 90 oz/sy and are well-suited to a range of applications. To find out more about our silicone glass fabrics and how they would work in your application, get in touch with the team today.