The performance of an aluminium smelter depends heavily on the integrity of its sealing systems. At the heart of each smelter are reduction cells, the electrochemical units where alumina is converted into molten aluminium. Inside a reduction cell, even small gaps can disrupt draft control, reduce energy efficiency, and allow fluorinated gases to escape into the potroom. Sealing systems in aluminium smelters protect reduction cell structures, penetrations, and adjacent equipment, support environmental compliance, and help maintain the heat balance required for stable metal production.

The Harsh Conditions That Make Sealing in Smelters So Challenging

Sealing applications in aluminium smelters are governed by the operating conditions generated through the reduction process. Seals installed around reduction cells must perform reliably while exposed to high temperatures, chemical attack, abrasion, and mechanical movement, often at the same time. aluminium smelter environments subject sealing materials to the following conditions:

- Sustained high temperatures

- Frequent thermal cycling

- Chemically aggressive atmospheres such as hydrogen fluoride (HF) and fluorides

- Abrasive alumina and carbon dust

- Mechanical stresses from component movement

- Long service intervals that limit replacement opportunities.

As these conditions occur simultaneously, effective sealing materials must balance thermal stability, chemical resistance, mechanical strength, and flexibility to maintain reliable containment over the operating life of the reduction cell.

Where Sealing Is Required in Aluminium Smelters

Aluminium smelters’ sealing applications are concentrated at interfaces where heat loss, gas leakage, and mechanical movement intersect. Every sealing location presents a distinct combination of thermal, chemical, and mechanical stresses, requiring solutions tailored to the demands of the specific interface.

Anode Bar Penetration Points

Anode bar penetrations are among the most leakage-prone areas of the reduction cell enclosure. Effective sealing limits the release of fluorinated gases, supports consistent draft control, and helps sustain uniform potline conditions. Degraded seals at these points can disrupt airflow balance and complicate emissions management, so maintaining seal integrity at anode bar penetrations is vital for reliable draft control and emissions performance.

External Cathode Bar Penetrations

Sidewall penetrations around external cathode bars are key to thermal containment. Proper sealing reduces heat loss around cathode blocks, protects sidewall linings, and supports stable energy performance. Inadequate sealing at the sidewall penetrations can accelerate heat escape and contribute to premature structural wear.

Hooding, Doors, and Access Assemblies

Hooding systems, doors, and access panels are handled routinely as part of normal smelter operations. Frequent opening and closing places repeated stress on seals, increasing the likelihood of wear, loss of compression, or misalignment over time. Sealing materials at these interfaces must remain flexible and durable to maintain containment and support consistent fume collection efficiency.

Crucible, Furnace, and Tapping Interfaces

Crucible, furnace, and tapping interfaces are exposed to steep temperature gradients along with fumes and particulates generated during operations. Sealing at crucible, furnace, and tapping interfaces helps control smelting operations and protects personnel by limiting the release of heat, dust, and gases.

Sealing Solutions for Aluminium Smelters

Mid-Mountain Materials, Inc. has developed sealing systems tailored to the specific challenges of the smelting environment. Every sealing solution combines high-temperature capability with chemical resistance and mechanical durability.

THERMOPAK® High-Temperature Seals

THERMOPAK® High-temperature seals are made from advanced fibre matrices that are impregnated and coated with high-temperature binders and protective finishes to enhance resistance to heat and abrasion. They are suitable for penetrations, access areas, and any location within the aluminium smelter that requires flexibility and resilience.

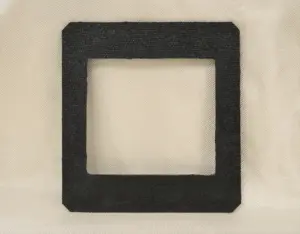

THERMOPAK® Anode Bar Seals

Designed to fit around anode bar penetrations in aluminium smelters, THERMOPAK® Anode Bar Seals limit the release of fluorinated gases and contribute to stable draft control. Their construction allows them to accommodate movement while maintaining a reliable seal.

THERMOPAK® External Cathode Bar Seals

These long-life sealing systems deliver near-hermetic performance at sidewall penetrations within aluminium smelters. By protecting cathode structures and reducing heat loss, they support the thermal balance of the reduction cell.

ARMATEX® Silicone-Coated Fiberglass Fabrics

Used for furnace doors, crucible lids, hood components, and sealing boots, ARMATEX® Silicone-coated fiberglass fabrics provide a robust combination of abrasion resistance, chemical stability, and thermal insulation, ensuring reliable sealing performance in demanding smelter operating conditions.

High-Temperature Ropes, Tapes, and Tadpole Gaskets

Such flexible materials support sealing in doors, flanges, and irregular joints. They are engineered to remain effective through repeated opening cycles and often complement bar seals to form a fully integrated sealing system.

How Operators Choose the Right Sealing Solution

Selecting an effective sealing system begins with comprehending the conditions at the sealing interface within the aluminium smelter. Temperature exposure is important, and materials must match the thermal environment while remaining stable through cycling. Chemical compatibility matters as well, particularly in areas exposed to HF and fluoride vapors that can rapidly degrade incompatible sealing materials.

Effective sealing material selection in aluminium smelters is guided by several key performance criteria, including:

- Continuous temperature rating

- Compatibility with fluorinated gases

- Resistance to abrasion

- The ability to conform to the geometry or movement of the sealing interface

- Expected durability over the intended operating campaign.

Applying such criteria ensures operators can choose sealing materials that support containment, improve heat retention, and stabilize potline performance.

Enhancing Aluminium Smelter Performance with Mid-Mountain Material’s Sealing Systems

Sealing is intrinsic to the successful operation of aluminium reduction cells within aluminium smelters. Thermal efficiency, emissions control, and equipment longevity all rely on the performance of the seals installed at key sealing interfaces throughout the aluminium smelter. Mid-Mountain Materials, Inc. provides sealing systems, including THERMOPAK® Anode Bar Seals, THERMOPAK® External Cathode Bar Sealing Systems, THERMOPAK® Crucible Lid Seals, ARMATEX® Coated Fabrics, THERMOSEAL® Moldables and Cement, and THERMOPAK® High-temperature Gasket materials, that ensure consistent containment, thermal control, and long-term reliability in aluminium smelter operations. To learn more about our sealing products for aluminium smelters, contact our specialists now.