Industry and the environment are antonymic concepts. Energy-intensive industrial processes produce millions of cubic tons of harmful greenhouse gasses every year, notwithstanding their effluent production materials nor potentially damaging extraction protocols. Numerous environmental policies, improved industry regulations, and advanced materials for thermal insulation have been applied to help improve the sustainability of crucial industry sectors, and to reduce greenhouse gas emissions to tolerable levels.

Emissions Control: Aluminum Case Study

The aluminum industry is one of the largest global industries, owing to the material’s versatility and its abundance. Alumina (AlO) is among the amplest raw manufacturing materials on earth, and it is routinely extracted through bauxite mining processes then forged into aluminum ingots for application in fields ranging from transport to water purification. However, this exhaustive chain of supply and manufacture has a significant carbon footprint. Aluminum production requires roughly 211 gigajoules (GJ) per ton, almost ten times the energy demand of steel manufacturing – and the aluminum sector is continuing to grow.

Emissions control is increasingly important to global markets, with a growing sense of environmental conscientiousness affecting industries across the world. All sectors are working to reduce their carbon footprints and improve their ecological policies, but regulated emissions levels cannot be achieved through legislation alone. Industrial facilities must be equipped with advanced thermal insulation to reduce emissions and conserve energy at the source. This is the single-most effective way to safeguard both our environment and our integral industries.

Mid-Mountain Materials supplies a selection of thermal insulation products for emissions control applications – including thermal insulation for the aluminum sector.

Thermal Insulation for the Aluminum Industry

Materials used in the aluminum industry must perform to a range of stringent specifications and requirements, providing outstanding component resistances to high temperatures, moisture, chemical corrosion, and molten splash, while conforming to environmental regulations. Thermal insulation for emissions control in the aluminum sector includes:

- Gaskets, exhaust manifolds, and exhaust duct connectors.

- Thermal insulation seals for doors, pot cells, and side shields;

Much of the energy demand of primary aluminum processing facilities comes from the electrolysis process, where alumina is dissolved in molten cryolite and inorganic catalytic powders at temperatures of up to 1000°C (1832°F). This process typically takes place in ceramic pots or specialized pot rooms. Applying robust thermal insulation to end doors and side shields can radically improve a facility’s overall energy conservation.

Mid-Mountain’s lines of ARMATEX® Q and ARMATEX® SQ coated fabrics and textiles is widely used for industrial thermal insulation, with heavyweight silicone coatings on one side of the flexible substrate and a low-porosity refractory coating on the anterior side. This matrix enables aluminum manufacturers to integrate high-quality thermal insulation into existing processes with minimal invasiveness and maximum energy conservation.

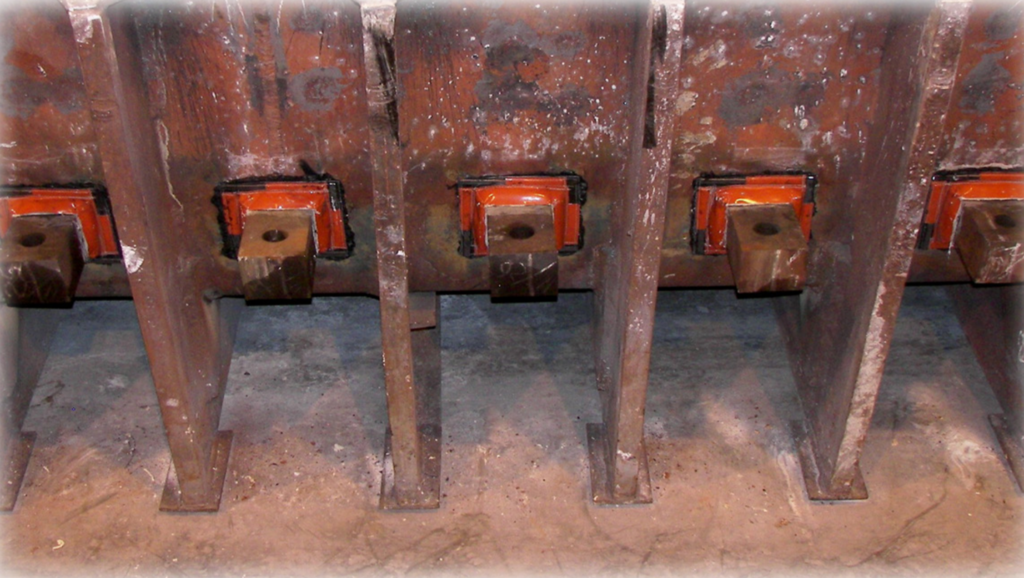

Our THERMOPAK® External Cathode Bar Seals are also excellent thermal barriers for aluminum processing. Comprised of ARMATEX® SQ and SF Fabric, with THERMOSEAL® Moldable and Cement for sealing and adhesion, it provides the most economical solution for energy conservation in primary aluminum smelters.

Our thermal insulation materials have established emissions control benefits, with proven applications for sealing and insulating vital industrial components.

Thermal Insulation from Mid-Mountain Materials, Inc.

Mid-Mountain Materials, Inc. is a leading supplier of thermal insulation products for numerous sectors. Our products have found significant applications in various industrial processes, supporting concerted industry efforts to reduce emissions and improve processing sustainability.

Our proprietary line of ARMATEX® coated fabrics are available at a range of specifications, with demonstrable applications beyond the aluminum industry.

If you would like any more information about our thermal insulation products, please do not hesitate to contact us.