Originally published on 01/26/22. This article has been updated with the latest information on PTFE coatings.

The safety of industrial coatings has become an increasingly important topic as research advances our understanding of per- and polyfluoroalkyl substances (PFAS). PTFE (polytetrafluoroethylene), commonly known by the brand name Teflon, remains a versatile coating used across numerous industries due to its excellent chemical resistance and wide temperature tolerance.

However, evolving research and regulatory changes have raised important questions about its environmental impact and potential health effects. This updated exploration examines the latest scientific understanding, regulatory developments, and available alternatives to PTFE coating.

Recent Regulatory Developments (2023-2025)

The landscape of PFAS regulation, which includes PTFE compounds, has changed significantly in recent years. The EPA has taken substantial steps to address these “forever chemicals” through several key actions:

- In April 2024, the EPA finalized a critical rule designating two widely used PFAS compounds – PFOA and PFOS – as hazardous substances under the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), also known as Superfund. This designation, effective July 8, 2024, represents a major shift in accountability for PFAS contamination.

- Earlier, in January 2024, the EPA finalized a rule preventing companies from starting or resuming the manufacture of 329 PFAS chemicals that have not been manufactured or used for many years without a complete EPA review and risk determination. This proactive measure aims to prevent potential reintroduction of these substances without proper safety assessment.

- Additionally, in October 2023, the EPA enhanced reporting requirements for PFAS to the Toxics Release Inventory (TRI) by eliminating an exemption that allowed facilities to avoid reporting PFAS when used in small concentrations. This change improves transparency and data collection about PFAS usage and release.

Despite these developments in the United States, as of September 2024, there is currently no specific UK or EU legislation governing PFAS products, although regulatory changes are anticipated in these regions as well.

Safer Alternatives to PTFE Coating

As awareness of potential PFAS concerns grows, the market for alternatives has expanded significantly. Here are several promising options:

Ceramic Coatings

Ceramic-based coatings have gained popularity as a PTFE alternative. These coatings typically use mineral oxides applied in layers. Benefits include:

- Higher heat resistance (typically up to 800°F)

- Greater durability and scratch resistance

- PFAS-free composition

- Often more environmentally friendly manufacturing processes

Silicone-Based Coatings

Silicone coatings provide another alternative with different performance characteristics:

- Excellent flexibility

- Good temperature resistance

- Non-toxic composition

- Usually more suitable for bakeware than everyday cookware

Polyurethane Coatings

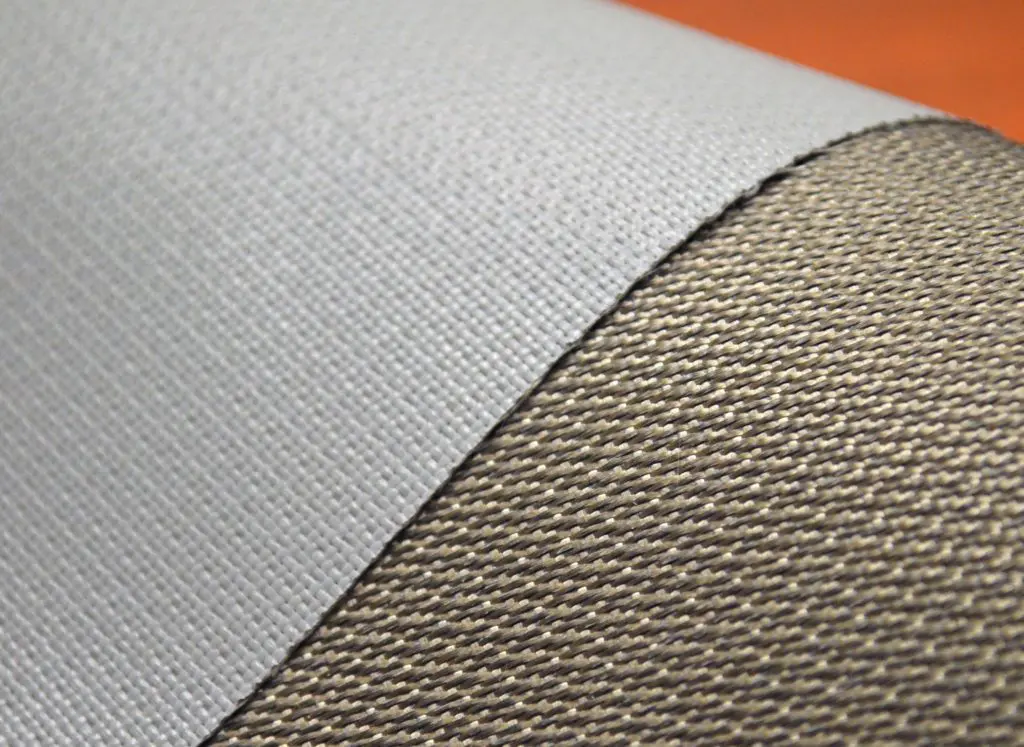

At Mid-Mountain Materials, our flagship PTFE-free coating solution is a polyurethane (PU)-based system that can provide similar benefits to PTFE while being safer for the environment. Our ARMATEX® PUF Coated Fabric series is a safer and highly effective alternative to PTFE-coated fabrics for industrial applications. These fabrics use a high-strength fiberglass base coated with polyurethane, merging the heat resistance and tensile strength of glass fiber with the versatility and durability of PU. Performance-wise, ARMATEX® PUF Coated Fabrics are exceptional:

- Thermal and Fire Resistance: The fiberglass base withstands temperatures up to 1,000°F (538°C) and is non-combustible. PU coatings can be made fire-retardant for added safety in high-risk environments.

- Chemical and Oil Resistance: PU-coated fabrics resist oils, chemicals, and solvents, making them suitable for harsh industrial settings.

- Waterproofing and UV Protection: The PU coating provides waterproofing and protects against UV degradation, enhancing outdoor durability.

- Mechanical Strength: These fabrics offer high tensile strength (300–700 MPa), abrasion resistance, and structural stability while remaining lightweight and flexible for easy fabrication.

- Insulation: They provide excellent electrical and thermal insulation, similar to PTFE-coated options.

Comparing Performance and Safety: Making Informed Choices

When evaluating alternatives to PTFE, several factors should be considered:

Performance Considerations

While alternatives are improving, some may not match PTFE’s chemical resistance in certain applications. Manufacturers and consumers should evaluate specific needs against available options.

Cost Implications

Some alternatives may be more expensive initially, though their longer lifespan and reduced environmental impact can offset these costs over time.

Environmental Benefits

The primary advantage of PTFE alternatives is their reduced environmental footprint. Unlike PFAS compounds that persist indefinitely, many alternatives are biodegradable or have substantially shorter environmental lifespans.

Health Considerations

As research continues to investigate potential health impacts of various coatings, choosing alternatives with well-established safety profiles can provide peace of mind for both manufacturers and consumers.

The Evolving Landscape of Coating Technology

As we navigate through 2025, the conversation around PTFE safety continues to evolve alongside regulatory frameworks and scientific understanding. While PTFE-based coatings remain widely used, increasing awareness of environmental and potential health concerns has accelerated the development and adoption of alternatives.

For manufacturers committed to environmental protection and consumer safety, exploring and implementing these alternatives represents not just a response to regulatory pressure but an opportunity to lead innovation in their respective industries. Consumers likewise have more options than ever to make informed choices aligned with both their practical needs and their values regarding environmental and health protection.

The future of coating technology will likely continue toward more sustainable, safer materials that maintain or improve upon the performance characteristics that made PTFE popular in the first place.

References

- The 2024 EPA PFAS Regulations, EPA PFAS Enforcement Priorities, and Reopener Risks. Buchanan. https://www.bipc.com/the-2024-epa-pfas-regulations,-epa-pfas-enforcement-priorities,-and-reopener-risks

- Key EPA Actions to Address PFAS. EPA. https://www.epa.gov/pfas/key-epa-actions-address-pfas