Originally published on 03/15/2018. This article has been updated with the latest information on thermal insulation materials.

High temperatures challenge performance in sectors like manufacturing, energy, and aerospace. Without proper insulation, heat moves through systems, reducing efficiency and increasing emissions. Engineers use thermal insulation materials to manage this risk. These materials reduce conduction, limit convection, and reflect radiation—preserving system integrity and improving operational control.

Broadly speaking, an insulation material is a substance used to reduce or resist the transfer of heat, sound, electricity, or other forms of energy from one side to another. Specifically, thermal insulation materials are designed to reduce heat transfer between objects or spaces by resisting conduction, convection, and radiation of heat. There are a range of material types available to achieve these goals in industry.

Types of Industrial Thermal Insulation Materials

- Fibrous materials such as fiberglass, rock wool, slag wool, cellulose, and natural fibers. These bulky materials resist heat flow primarily by trapping air and reducing conduction and convection.

- Cellular materials like rigid foam boards made from polystyrene, polyurethane, or polyisocyanurate. These materials contain gas-filled cells that reduce heat transfer and can come in forms like boards or sprayed foam.

- Reflective insulation materials, such as highly reflective foils, which reflect radiant heat away and are especially effective in warm climates. These materials act as radiant barriers and can also serve as vapor barriers.

- Granular materials like vermiculite and perlite, which have voids or hollow spaces that reduce heat transfer.

Let’s explore some specific material types and the applications they are used in.

Advanced Engineered Solutions: Mid-Mountain’s Material Technologies

ARMATEX® Coated Fabric Systems

Mid-Mountain’s ARMATEX® range represents a comprehensive family of coated fabrics engineered to address the most demanding thermal protection requirements. These materials combine advanced fiber substrates with specialized coating technologies to create multi-functional thermal barriers that excel in extreme environments.

Silicone Coated Configurations

ARMATEX® Silicone Coated Fabrics comprise varying substrates coated with silicone rubber compounds, engineered specifically for environments requiring chemical, abrasion, or heat and flame resistance. Available with base fabrics of aromatic polyamide, fiberglass, or silica, these materials find widespread application in removable pad insulation, thermal insulation barriers, and protection from weld spatter and slag. The silicone coating provides excellent flexibility and chemical resistance while maintaining thermal protection capabilities across extended temperature ranges.

The selection of substrate materials allows engineers to optimize performance characteristics for specific applications. Aromatic polyamide substrates offer exceptional strength-to-weight ratios and chemical resistance, making them ideal for aerospace and military applications. Fiberglass substrates provide cost-effective solutions for industrial applications where high strength and temperature resistance are required without the premium associated with specialized aramid fibers. Silica substrates deliver the highest temperature capabilities for applications involving extreme thermal exposure.

Refractory Coated Systems

ARMATEX® Q Refractory Coated Fabrics represent advanced thermal protection solutions composed of varying substrates impregnated with proprietary refractory compounds. These materials demonstrate enhanced temperature, chemical, and abrasion resistance while maintaining low porosity characteristics that prevent heat penetration. The substantial weight of these fabrics reflects their robust construction, making them suitable for severe environments where lighter materials would fail to provide adequate protection.

Primary applications include high-temperature resistant curtains, blankets, and seals in industrial environments where sustained exposure to extreme heat occurs. The proprietary refractory compounds provide exceptional thermal stability while the substrate materials contribute mechanical strength and dimensional stability under thermal stress.

Hybrid Silicone/Refractory Technologies

ARMATEX® SQ coated fabrics represent the pinnacle of thermal protection engineering, featuring high-temperature resistant substrates with proprietary refractory coating on one side and silicone rubber coating on the other. This dual-coating approach creates materials ideally suited for applications requiring increased chemical and abrasion resistance, high strength, and excellent thermal insulation in a single solution.

The engineering sophistication of these hybrid materials allows them to address multiple performance requirements simultaneously. The refractory side provides maximum thermal protection and structural integrity under extreme heat exposure, while the silicone side offers flexibility, chemical resistance, and ease of handling. Typical applications include die-cut parts, emission control seals, and welding blankets, pads, and curtains where the combination of thermal protection and mechanical performance becomes critical.

HYTEX® High-Temperature Textile Systems

The HYTEX® product family represents Mid-Mountain’s comprehensive approach to high-temperature textile engineering, offering materials with operational temperatures spanning from 400°F to 5000°F in oxygen-free environments. This extensive temperature range enables engineers to select materials precisely matched to their application requirements while ensuring optimal performance and cost-effectiveness.

Moderate Temperature Applications

HYTEX® 400 and 500 series materials address applications in the moderate temperature range while providing specialized performance characteristics. The Kevlar® industrial textiles offer organic aramid fiber construction with high chemical resistance, excellent dimensional stability, and moderate thermal resistance. These lightweight, high-strength materials are available in woven knit or braided knit configurations, allowing engineers to optimize mechanical properties for specific loading conditions.

Nomex® fabrics extend performance into applications requiring enhanced abrasion resistance, high strength, and flame resistance. The availability in multiple construction formats, including woven, woven knit, and braided knit configurations with various thickness options, provides design flexibility for aerospace and automotive components where space constraints and weight considerations are critical.

Extreme Temperature Solutions

At the extreme end of the temperature spectrum, specialized ceramic fiber compositions enable operation in environments that would destroy conventional materials. Alumina-boria-silicate fibers, as utilized in HYTEX 2200 Woven Fabrics, represent advanced ceramic technology specifically engineered for aerospace applications3. The ability to pass the FAA’s 2000°F 15-minute flame penetration test demonstrates the exceptional thermal protection capabilities of these materials.

These extreme temperature materials find application in aerospace thermal protection systems, furnace linings, and other critical applications where material failure could result in catastrophic consequences. The combination of thermal stability, mechanical strength, and dimensional integrity under extreme conditions makes them indispensable for applications at the forefront of thermal protection technology.

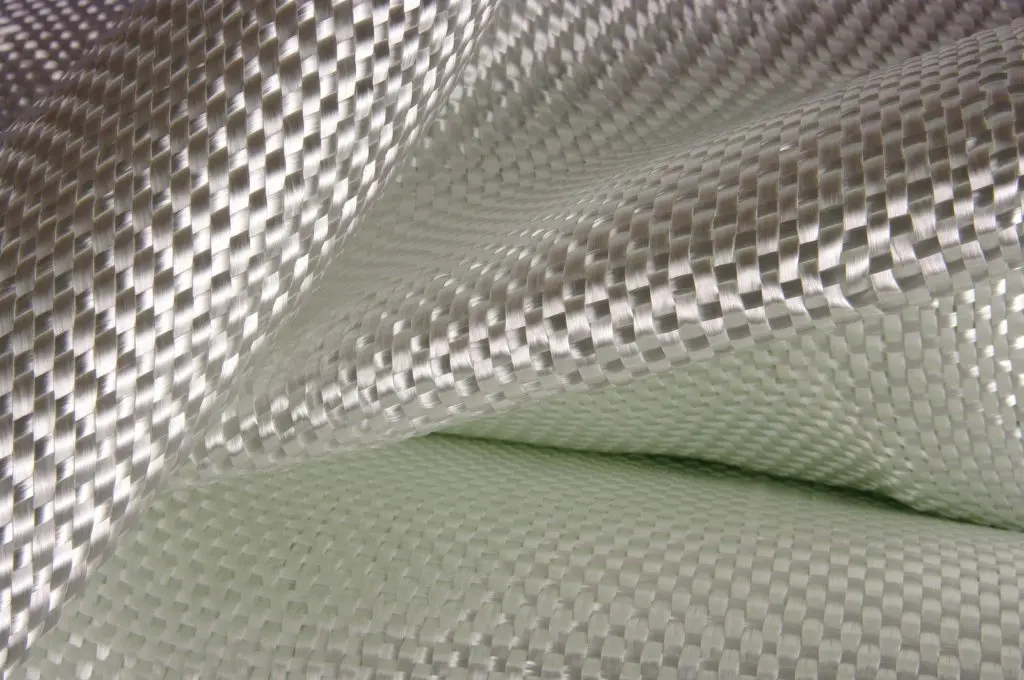

HYTEX 1000 Woven Fiberglass Fabric

THERMOSEAL® Refractory Products

THERMOSEAL® refractory materials represent Mid-Mountain’s expertise in bulk refractory fiber technology, encompassing cements, coatings, and moldables designed for high-temperature sealing and thermal insulation applications. These materials leverage the thermal protection capabilities of refractory fibers while providing the workability and versatility required for complex industrial installations.

Refractory cements offer the ability to create custom thermal barriers that conform to complex geometries while providing exceptional temperature resistance and thermal stability. These materials can be applied in various configurations, from thin protective coatings to substantial thermal barriers, depending on application requirements. The moldable variants provide additional versatility for applications requiring formed thermal protection elements with precise dimensional control.

Insulation Materials from Mid-Mountain

The selection of appropriate insulation materials requires careful consideration of multiple factors including operational temperatures, environmental conditions, mechanical requirements, and specific performance objectives. As industries continue to push the boundaries of operational conditions while demanding improved efficiency and sustainability, the development of advanced insulation materials remains critical to enabling these advances.

Mid-Mountain Materials, Inc. designs and manufactures advanced insulation materials tailored to meet diverse performance needs. Our engineered solutions draw on proprietary material technologies that support thermal efficiency and durability. For detailed information or technical support, contact our team directly.