Originally published on 03/15/2022. This article has been updated with the latest information on high-performance fabrics for aerospace applications.

Aerospace systems operate in conditions that test every material to its limit. Fabrics must withstand extreme heat, resist chemical exposure, and remain structurally sound without adding unnecessary weight. For decades, Mid‑Mountain Materials, Inc. has focused on designing high performance fabrics that meet the rigorous demands of aerospace environments, offering solutions focusing on thermal insulation, fire containment, structural reinforcement, and launch infrastructure protection. Each high performance fabric is developed to address specific operational stresses, helping aerospace systems manage heat and maintain structural integrity.

Why High Performance Fabrics Matter in Aerospace

High performance fabrics are engineered to remain stable and functional under extreme stress. Aerospace applications subject materials to high heat, chemical exposure, vacuum conditions, and heavy mechanical load. To endure, these high performance fabrics must deliver:

- High thermal resistance (withstanding temperatures exceeding 2000 °F/1093°C)

- Chemical and abrasion resistance

- Low outgassing for vacuum compatibility

- Lightweight strength to improve fuel efficiency

Each of the capabilities enable the high performance fabrics to insulate launch vehicles, shield engine components, and contain fires within aircraft systems.

Aerospace High Performance Fabrics From Mid‑Mountain Materials, Inc.

Since 1976, Mid‑Mountain Materials, Inc. has specialised in high performance fabrics built for aerospace systems under extreme thermal and mechanical stress. Our ARMATEX®, HYTEX®, CERMEX®, and THERMOPAK® ranges are developed to address the distinct challenges of flight, propulsion, and launch infrastructure, while meeting rigorous standards for fire protection and material emissions.

ARMATEX® Coated Fabrics

ARMATEX® Coated Fabrics are designed for demanding aerospace environments where thermal protection, fire resistance, and mechanical strength are critical. Generated from fiberglass or silica base cloths and coated with silicone or intumescent layers, such fabrics perform reliably under continuous movement, abrasion, and heat. Silicone-coated variants offer the flexibility needed for insulation wraps and moveable components, while intumescent coatings expand when exposed to high temperatures, forming a protective char that helps contain fire and isolate critical systems.

Within this range, ARMATEX® SF 37 JETSTAR delivers proven performance in flexible closure assemblies for aircraft loading walkways, where abrasion resistance and weathering stability are essential. For internal fire containment, ARMATEX® NF 14 CARGO TEX meets FAA requirements for flammability and smoke density, supporting safety in cargo liner applications. Together, these fabrics highlight how the ARMATEX® Coated Fabrics line supports aerospace safety across both ground operations and in-flight conditions.

HYTEX® Woven Textiles

HYTEX® High Performance Fabrics and Textiles are knit, woven, or braided from advanced fiberglass, silica, and ceramic fibers, delivering the thermal endurance and mechanical strength required in propulsion systems. They are used to shield components against continuous heat and vibration, helping maintain system stability over time. HYTEX® 1400, known for its flexibility and reliable thermal protection, is often used where lighter-weight insulation is needed. Meanwhile, HYTEX® 2200 is suited to harsher thermal and mechanical conditions. When used across aerospace platforms, both grades are crucial to maintaining structural performance in high-demand environments, including afterburner and exhaust systems, rocket and jet engine compartments, and thermal protection assemblies in spacecraft.

CERMEX® Thermal Insulation

Aerospace systems demand insulation that can perform under extreme thermal stress. CERMEX® Thermal Insulation delivers that performance in the form of durable mats and blankets made from fiberglass, silica, or ceramic fibers. Serving as reliable thermal insulation for aircraft, CERMEX® has a service range reaching 2300°F (1260°C) and helps protect engine bays, nacelles, and sealing interfaces to counter damaging heat. Its flexibility allows precise installation, establishing it as a trusted choice for thermal control across complex aerospace structures, like firewalls, battery compartments, and fuel tanks.

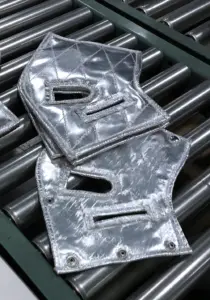

THERMOPAK® Fire Curtains, Seals, and Blankets

THERMOPAK® Fire Curtains, Seals, and Blankets are custom fabricated and designed to slow flame spread and contain heat within defined areas of an aircraft. Constructed from layered, high-temperature fabrics, they combine flexibility with thermal stability. Each part is tailored for installation in locations including cargo bays, firewall partitions, and engine compartments. By limiting heat transfer and defending surrounding components, THERMOPAK® Fire Curtains, Seals, and Blankets support compliance with strict aerospace fire safety standards. Such targeted containment helps prevent thermal escalation and safeguards critical systems during in-flight or on-ground fire events.

Strategic Fit for New Space and Commercial Aviation

As aerospace advances toward reusability, electrification, and longer mission durations, Mid‑Mountain Materials, Inc. delivers high performance fabric solutions that align alongside the industry’s most ambitious developments.

Our high performance fabrics can be used in:

- Reusable launch vehicles

- Electric and hybrid-electric propulsion systems in sustainable aviation

- High-speed aerospace projects.

Deep space missions and rapid flight demand materials engineered for precision and endurance. Mid-Mountain Materials, Inc. has high-performance fabrics that offer thermal stability, fire resistance, and mechanical strength tailored to the evolving needs of aerospace. With a focus on the future of aerospace, our fabrics contribute to advancing safer and more sustainable flight solutions.

Meeting Aerospace‑Grade Performance Standards

The aerospace industry demands high performance fabrics that meet strict technical standards to ensure safety, reliability, and environmental compliance. At Mid‑Mountain, every product is developed to comply with the standards of spaceflight, defense, and commercial aviation programs. Our high performance fabrics are qualified to:

- ASTM E84 / E1354 (flame spread and heat release)

- NASA‑STD‑6001 (low outgassing)

- MIL‑I‑24244 (insulation and fire performance)

- FAA FAR 25.853 (flammability in aircraft interiors)

Mid‑Mountain’s ISO 9001:2015 certification, in-house testing, and active R&D ensure our solutions meet the evolving requirements of the aerospace industry.

Advancing Aerospace Performance with Fabric Innovation

High performance fabrics remain critical to meeting the physical and regulatory challenges of modern aerospace. Mid‑Mountain Materials, Inc. designs materials that solve real problems in flight, propulsion, and launch systems. To see how our high performance fabrics can support your next project, get in touch with our team.