COATED FABRICS & TEXTILES

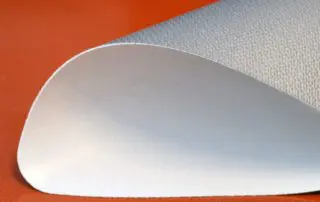

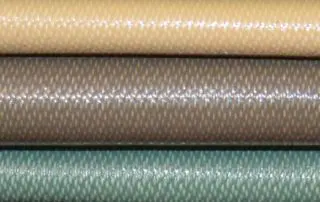

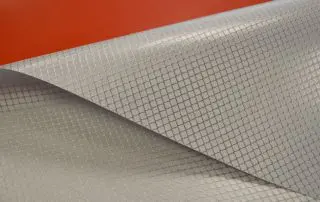

Manufactured with a variety of high-temperature resistant substrates and coatings to address your application requirements.

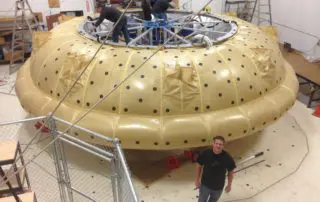

Mid-Mountain Materials, Inc. has been the leading supplier of precision coated fabrics and coated textiles for over 45 years. Our advanced, high-performance coated fabrics and industrial coated textiles are used in many applications across a broad range of industries, and can be fabricated, die-cut, or provided as rolled goods.

Utilizing some of the most advanced fibers, specialized weaves, and a variety of blends and coatings, our line of ARMATEX® Coated Fabrics and Textiles deliver not only superior heat protection but have exceptional durability and resistance to chemicals and abrasion.

Mid-Mountain began coating fabrics and textiles for industrial applications including welding fabrics, insulation fabrics, and thermal insulation barriers. Many of our standard products are used in industries such as welding, aluminum, petrochemical, insulation, aerospace, and automotive, and are comprised of silicone/fiberglass and silicone/silica combinations. Innovative engineering and working closely with our customers yielded more high-performance coated fabrics, giving us the unique ability to meet the requirements of a broad customer base.

Contact Us

We have application specific products to suit your needs. Please use the contact form to send your inquiry.

| Product | Highlights |

|---|---|

| Coated Fabrics & Textiles Features |

|

| Coated Fabrics & Textiles Standard Applications |

|

| Coated Fabrics & Textiles Specialty Applications |

|

Have a question?

Send us some information about what you’re looking for. Finding the right solution for industrial applications is what we do best.